The Saudi automotive industry is racing to reshape itself. The Public Investment Fund (PIF) and big global partners want the Kingdom to be making cars — lots of them — by 2030. The official baseline is clear: more than 350,000 vehicles a year, a mix of electric and petrol models. That target is being treated as the scorecard for an ambitious industrial plan tied to Vision 2030.

What’s happening now: Saudi automotive industry

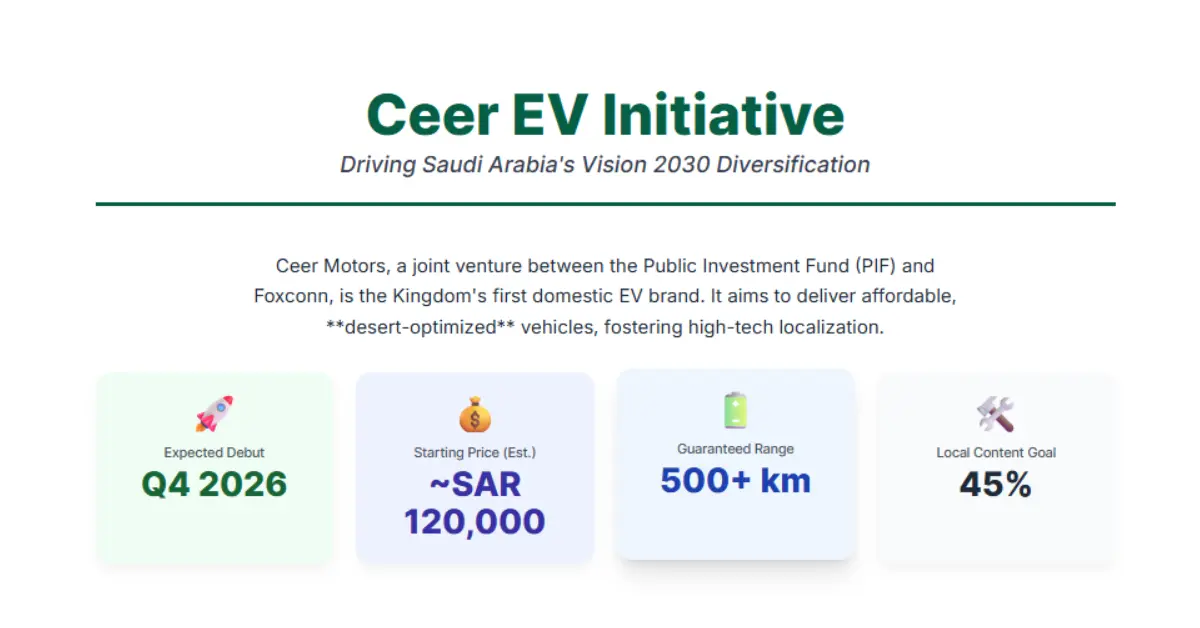

In the last two years, the PIF has signed major deals with Lucid, Hyundai and a new national brand, Ceer, to build factories and supply chains on Saudi soil. Lucid’s AMP-2 plant in King Abdullah Economic City opened and started re-assembly work in 2023. Hyundai and Ceer are on a fast track to begin local production in the next few years. These alliances are the backbone of the Kingdom’s push to go from importer to maker.

Why this matters

Saudi Arabia imports hundreds of thousands of cars each year and still depends heavily on oil exports. The government says building a local auto industry will diversify the economy, create jobs, and move technology into the Kingdom. The PIF isn’t just a passive investor — it is leading this change, putting money and strategy behind factories, brands and chargers to build demand and supply at the same time.

Production targets — one number, many meanings

Officials use different numbers. Saleh Al-Sulami from the National Industrial Development Center said the Kingdom expects to produce “more than 350,000 cars — both electric and internal combustion — by 2030.” That is the conservative, near-term benchmark many planners use. Elsewhere, ministers and industry notes point to higher EV-only ambitions — some statements aim at 300,000 EVs or even half a million electric cars by 2030 under an optimistic scenario. The difference matters: 350,000 is a reachable baseline; 500,000–600,000 EVs would require a much deeper local industry and faster market change.

Core partnerships (quick snapshot)

| Project | Model | Announced annual capacity | Start |

|---|---|---|---|

| Lucid AMP-2 | Re-assembly → EVs | 155,000 | Sep 2023. |

| Hyundai (HMMME) | PIF 70% / Hyundai 30% – ICE & EV | 50,000 | Groundbreaking 2023, production from 2027. |

| Ceer Motors | PIF/Foxconn national EV brand | 50,000 → aspirational 500,000 | Plant build underway; deliveries from 2026-27 planned. |

(See table above for the headline numbers. These projects together form the 350,000 baseline but the split between EVs and ICE will shift as the market and policy change.)

Voices from the field

Peter Rawlinson, CEO of Lucid, said opening AMP-2 was a historic step that supports Saudi ambitions to build a diversified economy. The company believes the plant can serve domestic demand and export markets. The PIF emphasizes that guaranteed government purchases will help de-risk this early production stage.

Balancing perspective: the doubts

Many analysts warn that money alone cannot create a complete car industry overnight. Toyota famously declined talks in 2019, citing high labor costs, a small domestic supplier base and other challenges — a reminder that auto companies look for deep local ecosystems, not just factories. Building Tier-1 and Tier-2 suppliers, battery component makers and semiconductor links is a long process, and Saudi Arabia is starting from little local automotive manufacturing.

Skills and supply chain — the real bottlenecks

Modern vehicle manufacturing needs skilled technicians, robotics experts, battery engineers and logistics managers. The Kingdom has launched training programs and an automotive academy, but expanding that talent pool takes time. Similarly, while the PIF is investing in tire plants and charging networks, a full ecosystem of hundreds of suppliers — the small firms that feed parts to big plants — is still being built. Without them, many factories will rely on imported kits, which delivers short-term numbers but limited long-term local value.

Market realities: fuel prices and consumer choice

There’s a political and economic tension at home. Saudi gasoline prices are still subsidized relative to many countries. That makes owning and running an internal combustion car cheap today and reduces the immediate money case for consumers to switch to EVs. To speed household adoption, the government will likely need either to reform fuel pricing gradually or to offer stronger consumer EV incentives. Academic studies also show infrastructure, climate, and perceptions matter heavily for buyer choices in the Kingdom.

Exports and the “Made in Saudi” pitch

A key goal is exporting cars. Lucid’s plan includes sending much of its output abroad. PIF aims for a “Made in Saudi” brand that can stand for quality and local content. But competing with mature exporters like Turkey or Morocco — who built deep supplier networks over decades — will be hard. Saudi Arabia’s route is different: use sovereign capital and strategic partnerships to jump directly to higher-value EVs rather than chasing low-cost mass production. That gives the Kingdom a chance to carve a niche, but it is not without risk.

What success would look like

If, by 2030, the Kingdom produces 350,000 vehicles while local content and supplier depth steadily rise, policymakers may call it a partial success. True, lasting success would mean local firms making battery packs, electronics, and many parts — and a workforce able to run R&D and high-value production lines. The measure isn’t just quantity; it’s the shift from kit-based assembly to vertically integrated manufacturing that creates enduring jobs and exports.

Recommendations from experts

Industry analysts suggest three priorities: (1) deepen and incentivize Tier-1/Tier-2 supplier entry, (2) scale vocational training and university partnerships fast, and (3) align consumer policy so EVs make economic sense (either by subsidy reform or targeted EV incentives). Securing direct access to minerals and battery supply — through investments or partnerships — is also key for resilience. These are the practical moves that money alone cannot substitute.

Outlook: realistic, not romantic

The PIF’s financial power and the high-profile partners make the Saudi automotive industry plan one of the boldest industrial experiments in the region. The 350,000 target is plausible as a baseline; the higher EV-only numbers are aspirational. How the Kingdom navigates supply chains, builds local skills, and reconciles consumer incentives with green goals will determine whether Vision 2030’s automotive chapter becomes a global success story or a costly lesson in the limits of money-driven industrial policy.

Final note

This project is still at an early, crucial stage. If the next few years deepen local supply chains, expand training, and make EV ownership more attractive at home, Saudi Arabia could move fast. If those pieces lag, the Kingdom may hit headline production numbers while missing the deeper industrial gains it seeks. Share this story if you think national industrial strategy matters — and keep watching how the Saudi automotive industry steers toward 2030.

Hey, I’m Arafat Hossain! With 7 years of experience, I’m all about reviewing the coolest gadgets, from cutting-edge AI tech to the latest mobiles and laptops. My passion for new technology shines through in my detailed, honest reviews on opaui.com, helping you choose the best gear out there!

2 thoughts on “Saudi automotive industry eyes 350,000 cars by 2030 — PIF bets billions on Lucid, Hyundai and Ceer”

Comments are closed.